Blog o automatizaci

Od optimalizace k autonomii – pět hlavních trendů automatizace výroby pro rok 2025 od společnosti OMRON

04. Leden 2025 S příchodem roku 2025 se blíží nová kapitola světa průmyslové automatizace. Podle teorie SINIC společnosti OMRON, která spojuje technologický pokrok se společenskými změnami, se nyní posouváme od optimalizace k autonomní společnosti. Teorie, kterou v roce 1970 vytvořil zakladatel společnosti OMRON Kazuma Tateishi, předpovídá budoucí společenský a technologický vývoj jako vodítko pro inovace. Ve fázi optimalizace se pozornost soustředila na zdokonalování procesů, zvyšování efektivity a využívání technologií ke zlepšení provozu. Autonomní společnost je ale zcela nová éra – doba, kdy systémy nefungují pouze efektivně; ale stávají se samoregulačními, samoučícími se a schopnými samostatného rozhodování.

Nad rámec techniky kvůli technice: Co se stane, když se průmyslová automatizace setká s provozní dokonalostí

30. Listopad 2024 V posledních několika letech došlo k rychlému technologickému pokroku, přičemž jako klíčový trend vyčníval vzestup umělé inteligence. V průzkumu mezi výrobci ve Velké Británii, USA a Kanadě 70 % dotázaných uvedlo, že do svých operací implementovalo nějakou formu umělé inteligence. Tato ochota přijmout nové technologie je impozantní, zejména proto, že zpracovatelský průmysl může automatizací tolik získat.

První kroky k úspěšné digitalizaci

12. Listopad 2024 Vybudování digitální továrny není samo o sobě cílem ani důvodem. Digitální továrna je nástroj, který poskytuje výrobním podnikům flexibilitu reagovat na změny na trhu – ať už jde o inovační trendy, nebo zvyšování nákladů, a ať už působí v potravinářském a nápojovém průmyslu, osobní péči, farmaceutickém, nebo automobilovém sektoru.

PPWR: proč jsou spolupráce napříč řetězci, sledovatelnost a inteligentní balení klíčové

24. Září 2024 Podle údajů Eurostatu vyprodukuje v roce 2021 každý obyvatel EU 188,7 kg obalů, což je téměř o 32 kg více než v roce 2011. Za toto období se množství plastového obalového odpadu zvýšilo o 27 %. Ačkoli se zvýšila i míra recyklace, stále se nerecykluje velké množství plastových obalů – podle nejnovějších statistik dosahuje 50% míry recyklace plastů pouze několik zemí v Evropě. Komise uznala, že stávající právní rámec nevede ke zlepšení v oblasti snižování množství obalového odpadu, a proto v roce 2022 navrhla revizi nařízení z roku 2018 o obalech a obalových odpadech (PPWR).Očekává se, že revidované nařízení PPWR vstoupí v platnost do konce tohoto roku a zásadně změní způsob navrhování, spotřeby a likvidace obalů. Aktualizované nařízení má široký záběr, ale jeho základním cílem je snížit množství vznikajících obalových odpadů a zvýšit recyklovatelnost obalů.

Jak předejít omezení efektivity: Proč by společnosti neměly odkládat své plány ohledně robotiky?

24. Září 2024 Odkládání investic do inovativních technologií je spojeno s mnoha riziky. Firmy, které stále váhají, by si měly položit tři otázky.Evropská ekonomika čelí řadě výzev, které ovlivňují její růst, stabilitu a konkurenceschopnost. Evropa má například jednu z nejstarších populací na světě. Stárnoucí pracovní síla zvyšuje zátěž na systémy sociálního zabezpečení a snižuje nabídku pracovních sil, což potenciálně zpomaluje hospodářský růst. Kromě toho závazek EU k zelené dohodě a dosažení uhlíkové neutrality do roku 2050 vyžaduje značné investice a strukturální změny v různých odvětvích. K tomu se přidává nedostatek ochoty investovat kvůli finančním starostem. Nedávná studie McKinsey Global Institute (MGI) zjistila, že velké evropské firmy s více než 1 miliardou dolarů v příjmech zaostávají za svými americkými protějšky. Dohromady investují o 400 miliard dolarů ročně méně a rostou o jednu třetinu pomaleji.Tato investiční únava může vést k několika problémům, které mají krátkodobé i dlouhodobé dopady, včetně nevýhod, pokud jde o konkurenceschopnost, udržitelnost a pověst, nižší produktivitu a menší úspěch při získávání nových kvalifikovaných pracovníků. Inovativní robotika může takovému vývoji čelit, ale vyžaduje také dobře promyšlené financování. Firmy, které v současnosti omezují své investice, by si proto měly urychleně položit otázku, zda to pro ně nebude mít dlouhodobě negativnější důsledky než krátkodobé úspory. Tyto tři otázky by se měly zaměřit na tyto úvahy:

Digitalizace s otevřenými standardy: Recept na kvalitní noční spánek

02. Září 2024 Můžeme se zavázat k mým predikcím? Dokážeme splnit termín? Mám dostatečný přehled, abych si mohl byl stoprocentně jistý? Jak si továrna vede z pohledu QCDE (kvalita, náklady, dodací lhůta a dopad na životní prostředí) v porovnání s našimi cíli a v porovnání s konkurencí? To jsou jen některé z obav, kvůli kterým nemůžou vedoucí továren spát – obav, které lze vyřešit pomocí digitalizace. V digitalizovaném výrobním prostředí se vedoucí továren nemusí obávat neznámých faktorů, rizik ani čehokoli, co by se mohlo přihodit. Digitalizace odbourává nejistotu a umožňuje dosažení optimalizace zaměřené na výkon. Přináší s sebou poznatky, které vedoucím továren pomohou zlepšit kvalitu, snížit náklady, zkrátit dodací lhůty a omezit dopad na životní prostředí. Vedoucí digitalizované továrny už se nebude muset uprostřed noci probouzet plný obav – ale pokud by se tak přeci jen stalo, krátký pohled na mobilní telefon ho ujistí, že vše funguje přesně tak, jak má. Přechod od probdělých nocí plných úzkosti k nocím naplněným poklidným spánkem ovšem není snadný. Dá se říct, že digitalizace může být celkem únavná. Vedoucí projektů si jen málokdy můžou dovolit luxus práce na nepopsané tabuli – většinou pracují s mozaikou starých technologií, které jsou tak nějak sešité dohromady; snaží se digitalizovat výrobní linky, jejichž součástí jsou stroje, které nikdy nezaznamenávaly data a byly postavené ještě před zrozením datových komunikačních protokolů. Kombinace tohoto všeho dohromady představuje značnou výzvu v oblasti integrace OT a IT.

Dynamické doplňování na straně linky: strategická odpověď na současné výrobní výzvy

15. Červenec 2024 Pokud si výrobci chtějí udržet efektivitu a konkurenceschopnost a zároveň čelit výzvám, které přináší přizpůsobení a nedostatek pracovních sil, je čas přehodnotit systémy a postupy doplňování na straně linky. Mohly by být odpovědí na tyto výzvy systémy AMR a koboti? Trend přizpůsobování přinesl výrobcům řadu provozních výzev. Potřeba pojmout širší škálu komponentů a materiálů přináší variabilitu, kterou tradiční systémy jen těžko efektivně zvládají. To může vést ke zvýšení nákladů na zásoby, prodloužení dodacích lhůt a zpoždění výroby. Empirická data podtrhují dopad přizpůsobení na výrobní operace. Výrobci uvedli, že čelili prodlouženým dodacím lhůtám, vyšším výrobním nákladům a potřebě řídit více zásob. Tato čísla ilustrují hmatatelné výzvy, které přizpůsobení představuje a které vyžadují inovativní přístupy k efektivnímu řízení této složitosti.

Robotické trendy 2024: Jednoduchá a flexibilní aplikace nezbytná k dosažení plného potenciálu

03. Červenec 2024 Od nosiče nákladu přes kolegu až po týmového hráče: role robotů se za posledních sedm desetiletí výrazně změnila. Umělá inteligence vytváří další možnosti, ale rozhodujícím faktorem zůstává člověk. Roboti, nebo lidé – kdo bude v budoucnu určovat výrobu? Od roku 1954, kdy si George Devol patentoval programovatelný manipulátor, vyvolává tato otázka diskuse. Devolův robot Unimate způsobil revoluci v průmyslu tím, že bezpečně vykonával nebezpečné úkoly, a zdůraznil, že nejde o souboj robot vs. člověk, ale spíše rovnice „robot + člověk = efektivita“. V průběhu 70 let se požadavky průmyslu vyvíjely tak, aby upřednostňovaly flexibilitu, škálovatelnost, přizpůsobivost a udržitelnost. Roboti zvládají úkoly, které uvolňují lidem ruce, aby se mohli soustředit na činnosti s přidanou hodnotou.

Spojování bodů: Automatizace podávání pro konkurenční výhodu

18. Červen 2024 Vývoj v oblasti robotiky usnadňuje koncepci flexibilních systémů podávání a manipulace na straně výrobní linky, které mohou zvýšit bezpečnost, produktivitu a kvalitu a zároveň řešit nedostatek pracovních sil. Tovární automatizace obvykle začíná body. Máme tím na mysli velké, finančně náročné závody, které provádí komplexní a viditelné úkoly přidané hodnoty – ať už jde o průběžné balení, vstřikování, balení blistrů, plnění lahví, paletizaci nebo jiné hlavní výrobní procesy. Linie, které spojují tyto body dohromady – manipulace, nakládání a systémy podávání – bývají spíše řešené druhotně, a to až do té míry, že se tyto činnosti často provádějí ručně. Může se zdát, že je jednodušší a levnější mít obsluhu, která nakládá suroviny na výrobní linku nebo podává komponenty do strojů, než utrácet za automatizaci. Jedná se však o krátkozraký pohled, který opomíjí mnoho obchodních výhod, které může automatizované podávání a manipulace na straně výrobní linky přinést z hlediska efektivity, kvality produktů, škálovatelnosti a bezpečnosti a ochrany zdraví. Je to také názor, který je stále více zastaralý vzhledem k tlaku, který na výrobní odvětví vyvíjí současná krize práce.

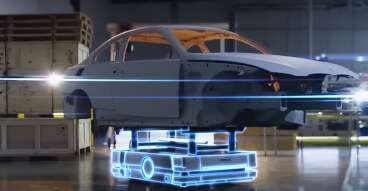

Čtyři největší výzvy, kterým výrobci elektromobilů čelí na cestě k dosažení udržitelné budoucnosti

17. Červen 2024 Elektromobily (EV) v posledních letech přešly ze specializovaného trhu na významnou průmyslovou sílu. Od roku 2023 tvoří elektromobily téměř pětinu prodaných vozidel, přičemž prodej vzrostl o 3,5 milionu kusů – což je podle Globálního výhledu EV 2024 IEA skok o 35 % oproti předchozímu roku. Očekává se, že tento nárůst bude pokračovat, přičemž odhady naznačují, že prodej na rozvíjejících se trzích v roce 2024 přesáhne 1 milion kusů, což oproti roku 2023 znamená 40% nárůst. Vlády po celém světě tlačí na snižování emisí CO2, což urychluje tento přechod na elektrická vozidla.Co to znamená pro výrobce automobilů? Za prvé to znamená, že musí přejít na navrhování a výrobu převážně elektrických vozových parků, což je krok, který již mnozí podnikli. Za druhé to znamená vybudování nových výrobních linek a zvládnutí nových výrobních procesů, což může být docela výzva.Právě zde přichází do hry důvěryhodný partner pro automatizaci. Partnerství s odborníkem v oblasti automatizace může pomoci zvládnout komplexní aspekty tohoto přechodu v celém odvětví. Díky širokému portfoliu technologií, globální podpoře a hlubokým odborným znalostem v oblasti automobilového průmyslu je společnost OMRON připravena vést výrobce na cestě k elektrifikaci.Tento příspěvek na blogu se bude zabývat hlavními výzvami v oblasti výroby elektromobilů a tím, jak může partnerství se společností OMRON poskytnout efektivní řešení:

Inteligentní automatizace jako hybatel změny

31. Květen 2024 Výrobní průmysl je zodpovědný za přibližně čtvrtinu globálních emisí skleníkových plynů¹, což jej řadí na druhé místo v podílu na emisích uhlíku, stejně jako dopravu. To znamená, že snížení uhlíkové stopy výrobního odvětví bude hrát zásadní roli při zmírňování našeho dopadu na změnu klimatu.Je načase, aby výrobní průmysl přestal být zdrojem problémů a začal naplňovat svůj potenciál tím, že se stane jedním ze zdrojů řešení, bude se zabývat změnou klimatu a využije automatizaci jako prostředek změny v tomto procesu.To odráží přesvědčení našeho zakladatele, že jako firma máme povinnost něco vrátit společnosti, ve které působíme. Před více než 90 lety se společnost OMRON zrodila z vize svého zakladatele Kazumy Tateišiho o využití technologií k vytvoření lepšího světa.Tateišiho étos „zlepšování života a přispívání k lepší společnosti“ nebyl vzhledem ke klimatickým výzvám, jimž jako společnost čelíme, nikdy relevantnější než v současnosti. Jak ale může výroba přinést pozitivní rozdíl?

I když to není rozbité, měli byste to opravit

04. Duben 2024 Udržitelnější výroba rychloobrátkového zboží díky inteligentnímu řízení spotřeby energie

Od optimalizace k autonomii – pět hlavních trendů automatizace výroby pro rok 2025 od společnosti OMRON

04. Leden 2025 S příchodem roku 2025 se blíží nová kapitola světa průmyslové automatizace. Podle teorie SINIC společnosti OMRON, která spojuje technologický pokrok se společenskými změnami, se nyní posouváme od optimalizace k autonomní společnosti. Teorie, kterou v roce 1970 vytvořil zakladatel společnosti OMRON Kazuma Tateishi, předpovídá budoucí společenský a technologický vývoj jako vodítko pro inovace. Ve fázi optimalizace se pozornost soustředila na zdokonalování procesů, zvyšování efektivity a využívání technologií ke zlepšení provozu. Autonomní společnost je ale zcela nová éra – doba, kdy systémy nefungují pouze efektivně; ale stávají se samoregulačními, samoučícími se a schopnými samostatného rozhodování.

Co přinese rok 2024 v oblasti automatizace? Šest předpovědí od společnosti OMRON Europe

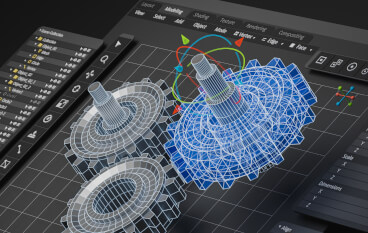

13. Prosinec 2023 Řada otřesů v posledních několika letech předznamenala novou éru zvýšených geopolitických a ekonomických rizik. Výrobci jsou nuceni k tomu, aby do obchodních modelů začlenili odolnost a flexibilitu a aby přehodnotili globální dodavatelské řetězce a vztahy. Zároveň stoupá tlak na začlenění principů ESG (ochrana životního prostředí, sociální aspekty a správa) do rozhodování o provozu. Pro vývoj řešení pro automatizaci a řízení, která mohou výrobnímu průmyslu pomoci se této nové realitě přizpůsobit, bude nezbytná umělá inteligence, datová věda, digitální dvojčata, technologie snímání a monitorování a kamerová technologie. V této souvislosti bych rád popsal šest hlavních trendů, které ovlivní průmyslovou automatizaci a budou ji formovat v roce 2024 a dalších letech.

Podpora pracovníků: Přístup společnosti OMRON k rozvoji dovedností v evropské výrobě

06. Září 2023 Probádáme neochvějný závazek společnosti OMRON rozvíjet dovednosti, které posilují příští generaci, zatímco se průmysl vydává na cestu transformace – cestu, která uvolňuje plný potenciál čtvrté průmyslové revoluce (4IR) a zároveň odvážně směřuje k páté průmyslové revoluci (5IR).Na akademických půdách, v zasedacích místnostech vizionářských vedoucích podnikatelů a v kancelářích pokrokově smýšlejících politiků se vyvolává vášnivá debata. Točí se kolem toho, že hluboký posun od čtvrté průmyslové revoluce (4IR), nebo jak se také říká Průmyslu 4.0, k Průmyslu 5.0 změní svět, ve kterém žijeme.Z historického hlediska byla průmyslová revoluce prvním věkem strojů, elektřina druhým, elektronika pak třetím a internet jako platforma čtvrtým věkem strojů. Nyní vstupujeme do pátého věku strojů, který zdůrazňuje harmonickou spolupráci člověka a stroje a přínos průmyslu pro společnost. Nastal okamžik, kdy je třeba se nejen přizpůsobit, ale stát se vůdcem, průkopníkem a vytvářet budoucnost, v níž inovace nezná hranic. Klaus Schwab, zakladatel a výkonný předseda Světového ekonomického fóra, poznamenal, že: „Stojíme na pokraji technologické revoluce, která zásadně změní způsob, jakým žijeme, pracujeme a navzájem se k sobě chováme. Svým rozsahem, působností a složitostí se tato transformace nepodobá ničemu, co lidstvo dosud zažilo. Náš svět prochází transformační změnou. Globální výroba se vyvíjí a je poháněna automatizací tradičních průmyslových postupů prostřednictvím inteligentních technologií, komunikace M2M a integrace internetu věcí. Tato synergie pohání zvýšenou automatizaci, bezproblémovou komunikaci a inteligentní stroje, které samostatně analyzují a diagnostikují problémy.Vzestup umělé inteligence vyvolává debaty a naznačuje hlubší proměny v rámci našeho společenského vývoje. Jak hledáme cestu touto dynamickou krajinou, jsme připraveni přijmout inovace a přetvořit naši budoucnost.

Od červených světel po roboty: Společnost OMRON slaví 90 let inovací

06. Červen 2023 Při příležitosti letošního Dne zakladatele se společnost OMRON ohlédla za 90 lety, během kterých posouvala technologické hranice. S očekáváním vyhlíží další inovace v oblasti automatizace, které se ponesou v duchu udržitelnosti, digitalizace a spolupráce mezi strojem a člověkem.10. květen – velký den Každoročně představuje 10. květen pro společnost OMRON patrně ten nejdůležitější den v kalendáři. V tento den si 30 000 zaměstnanců společnosti OMRON po celém světě připomíná život a odkaz jejího zakladatele Kazumy Tateišiho. Znovu se hlásí k Tateišiho vizi pomáhat pomocí technologie vytvářet lepší svět a plní své společenské závazky – často účastí na dobrovolnických a charitativních projektech ve svých komunitách. Milníky inovace Inovacemi lemovaná cesta společnosti OMRON začala v roce 1933 vývojem vysoce přesného časovače pro rentgen. Tehdy naše společnost poprvé pomohla odpovědět na společenskou poptávku po řešeních problémů. V roce 1960 společnost OMRON představila první bezkontaktní bezdotykový spínač na světě a přinesla tak revoluci pokročilých možností hromadné výroby. Od té doby přicházela a nadále přichází s dalšími průlomovými technologiemi, včetně první automatické dopravní signalizace, systému bezobslužných vlakových stanic, nositelného monitoru krevního tlaku, ultrarychlého regulátoru s fuzzy logikou a zařízení pro automatickou diagnostiku nádorových buněk.

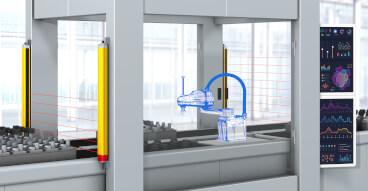

Dokáže umělá inteligence (AI) v robotických systémech spravovat části funkční bezpečnosti?

13. Duben 2023 Autoři: Josep Plassa, manažer marketingu bezpečnostních produktů ve společnosti OMRON Europe, a Atsushi Oshiro, manažer rozvojového střediska společnosti OMRONRoboty a systémy umělé inteligence se staly nedílnou součástí průmyslových výrobních závodů. Aby byla zajištěna bezpečnost pracovníků při používání robotů, je nezbytné podstoupit podrobné posouzení rizik. Toto posouzení se provádí z hlediska funkční bezpečnosti a zkoumá pět hlavních prvků využívaných roboty k určení autonomních řídicích akcí: Rozpoznávání prostředí, plánování akcí, generování trajektorie, řízení pohybu a měření.

Umělá inteligence: Nejsem hloupá

08. Únor 2023 Před deseti lety jsem byl docela pyšný na to, jak chytré jsou stroje v naší továrně. Se svou dnešní definicí chytrosti si uvědomuji, že byly vlastně docela hloupé.Proč? Protože i když dělaly to, pro co byly navrženy, jakmile nastalo něco neočekávaného nebo neobyčejného, zarazily se. Nezbylo jim než se zeptat obsluhy: „Co je se mnou v nepořádku?“.Odstraňování problémů a opětovné zprovozňování strojů vyžadovalo chytré lidi. Vysoce kvalifikované pracovníky obsluhy. Zkušené softwarové a hardwarové inženýry. Problém je v tom, že v posledních deseti letech se tito lidé stávají stále nedostupnějšími. V tomto odvětví jednoduše není dostatek nových talentů, aby se vyrovnaly počty pracovníků, kteří se nyní blíží k důchodovému věku. Když tito lidé odejdou do penze, odnášejí s sebou své těžce nabyté pracovní znalosti, které jsou výsledkem mnohaletých zkušeností. S každým odcházejícím pracovníkem se podniky potýkají s perspektivou méně produktivní a méně kvalifikované pracovní síly.

Cesta k nulovým emisím: O taktice

01. Únor 2023 Klíčem k budoucnosti s nulovými emisemi ve výrobě je transformace hodnotového řetězce prostřednictvím automatizace.V červnu 2022 časopis New Scientist uvedl, že třetina největších světových společností si dala za cíl dosažení nulových emisí – výrazně více než ve stejné době v loňském roce.Ačkoli je pozitivní zprávou, že se tempo zrychluje, článek dále uvádí, že podrobnosti o tom, jak společnosti plánují dosáhnout nulových emisí, se liší.To ve skutečnosti není překvapivé. Vytvoření a implementace strategie nulových emisí je velkým závazkem pro všechny podniky, zejména pro ty s 80 % emisí skleníkových plynů, které spadající do rozsahu 3 – jedná se o emise, které se vyskytují v hodnotovém řetězci vstupu nebo výstupu. To je výzva především pro společnosti vyrábějící rychloobrátkové spotřební zboží (FMCG), jejichž dodavatelské řetězce a následná logistika jsou dlouhé a složité.Většina těchto podniků ví, co musí udělat: dekarbonizovat a cirkularizovat hodnotový řetězec. A mají strategii, která se bude obecně týkat optimalizace využívání zdrojů a energie, nahrazení produktů a procesů s vysokými emisemi a snížení odpadu.Hlavní výzva ale spočívá v převedení záměru do akce. Právě zde hraje klíčovou roli automatizace.Sběr a analýza dat jsou klíčem k úspěšnému přechodu na nulové emise. Jak by bez toho společnosti věděly, jaký je jejich výchozí bod, kde se musí zlepšit, zda se zlepšily a do jaké míry? Spolehlivé údaje jsou základem pro přeměnu závazku ve změnu a pro důvěryhodnou a správnou komunikaci se zúčastněnými stranami a plnění klimatických cílů.

Překonání energetické a palivové krize pomocí automatizace

07. Prosinec 2022 Pokud chtějí být průmyslové podniky schopné čelit rostoucím cenám a splnit své ekologické cíle, měly by prozkoumat možnosti, jak jim mohou automatizační technologie z jednoho zdroje pomoci se strategií udržitelnosti.Vysoké ceny energií a paliv zatěžují jak domácnosti, tak průmysl. Tato situace nejen negativně ovlivňuje finanční plány a odčerpává finanční prostředky, ale nadměrné ceny dokonce nutí některé společnosti zastavit výrobu. Podle organizace Make UK 42 % dotázaných výrobců uvedlo, že jejich účty za elektrickou energii se za posledních 12 měsíců zvýšily o 100 %, a 32 % dotázaných výrobců uvedlo, že ceny plynu se za poslední rok zvýšily o více než 100 %. Znepokojivých 12 % výrobců již v přímém důsledku zvýšených účtů za energie zrušilo pracovní místa.Válka na Ukrajině, pandemie nemoci Covid-19 a ceny plynu jsou jen některé z příčin krize, která má dopad na všechna odvětví a ovlivňuje vše od cen elektřiny až po dodavatelské řetězce. Co by nyní měly výrobní společnosti zvážit? K dosažení větší flexibility a energetické efektivity je nezbytné přijmout komplexní strategie automatizace. Ty zahrnují inovativní robotiku spojenou se senzorovými a kamerovými technologiemi, stejně jako umělou inteligenci – místně zpracovávané algoritmy umělé inteligence. Kromě toho mohou data z výrobních závodů dostupná v reálném čase pomoci při odhalování anomálií a zlepšování celkové efektivity vybavení (OEE).

Jakým směrem se ubírá intralogistika? Tipy pro vyšší efektivitu

15. Listopad 2022 Někdy se tolik zaměřujeme na celkový obraz, že zapomínáme na detaily, kterými jsou však důležité procesy charakterizující inteligentní výrobu. Příkladem je intralogistika, tedy toky materiálů a zboží, které probíhají v prostorách společnosti nebo ve výrobní hale. Nedávná studie zjistila, že více než 80 procent dotázaných společností považuje zvýšené využívání umělé inteligence a automatizace v intralogistice za nezbytnou součást řešení problémů, jako je nedostatek kvalifikovaných pracovníků nebo plány růstu.Automobilové společnosti, které chtějí splnit požadavky trhu a zákazníků, zvýšit efektivitu a stát se udržitelnějšími, musí přijít s novými nápady. Náklady na energii, plynová krize a rostoucí inflace činí tento úkol ještě obtížnějším. Inteligentní tovární koncepty, které kombinují inovativní automatizaci, digitalizaci a inteligentní vnitropodnikové přístupy, mohou poskytnout cennou podporu. Někteří v této souvislosti hovoří o průmyslu 4.0, jiní o „továrně budoucnosti“, další dávají přednost průmyslovému internetu věcí (IIoT). Ale bez ohledu na to, jaký termín upřednostňujete, je nejdůležitější být aktivní a spoléhat se na spolehlivé partnery. Intralogistika je dobrým výchozím bodem pro rychlé zahájení změny. Situace je taková, že je naléhavě zapotřebí přijmout opatření, mnoho společností je totiž v současné době značně omezeno nedostatkem kvalifikovaných pracovníků. Moderní technologie, jako jsou mobilní roboty, mohou poskytnout nápravu.

Jak může adaptivní kontrola s využitím umělé inteligence přispět k flexibilitě výroby

04. Říjen 2022 Spotřebitelé dnes požadují produkty přizpůsobené jejich osobním potřebám a vkusu. Namísto výroby kusů, které jsou „určeny do regálu“ a „zaslány na sklad“, musí výrobci přizpůsobovat produkty, které jsou „určeny pro mě“ a „zaslány mně“. Tento přístup způsobuje revoluci ve výrobě a nutí společnosti měnit své procesy. Současně je nutné zajistit nulové množství reklamací a vad.Trénované oko zkušeného kontrolora rychle odhalí chyby, nicméně podobné rutinní úkoly bývají únavné a nelze je provádět v každém kroku výroby, zvláště při současném nedostatku pracovních sil v mnoha průmyslových oborech. Šel by však tento úkol automatizovat i ve vysoce smíšené nízkoobjemové výrobě? Dokázaly by inteligentní kamerové systémy nebo „elektronické oko“ napodobit rozpoznávací schopnost lidského oka s přidanou hodnotou opakovatelnosti a robustnosti? Nejnovější adaptivní kontrola využívající umělou inteligenci dokáže překonat problémy spojené s automatickou kontrolou kvality a zajistit tak vyšší flexibilitu, produktivitu a přizpůsobivost.

Umělá inteligence: Naděje, přehnané očekávání a strach, že něco promeškáme

22. Září 2022 Když jsme před deseti lety dostávali dotazy týkající se projektů založených na umělé inteligenci, vycházely především z přehnaného očekávání nebo strachu, že člověk něco promešká. Když jsem se těchto lidí zeptal, proč chtějí využívat umělou inteligenci, velice často se mi dostalo odpovědi „protože mi to dal za úkol můj šéf“, „protože máme spoustu dat“ nebo „protože se to zdá být zajímavé“. Žádný z těchto důvodů však nebyl dostatečně pádný a rozhodně neospravedlňoval tak obrovskou investici, kterou aplikace využívající umělou inteligenci v té době vyžadovaly.To se však mění a místo přehnaného očekávání nebo strachu, že něco promeškáme, za tím vším teď stojí spíše naděje. Zákazníci se už neptají, zda jim můžeme pomoci s umělou inteligencí. Ptají se, zda jim můžeme pomoci s prediktivní údržbou, kontrolou kvality nebo optimalizací procesů. Přicházejí k nám s problémem a chtějí, abychom jim ho pomohli vyřešit. Využívání umělé inteligence samo o sobě již není motivem ani cílem. Umělá inteligence se namísto toho stala nástrojem.Bez ohledu na odvětví – ať už jde o potraviny a nápoje, farmaceutický průmysl, elektroniku, nebo automobilový průmysl – je konečný cíl vždy stejný: vyrábět vysoce kvalitní produkty bez vad za nižší cenu, za použití méně energie a vynaložení méně práce. A umělá inteligence může být jedním z celé řady řešení, jak těchto cílů dosáhnout.

Automatizace se přizpůsobuje udržitelnému balení

16. Srpen 2022 Už jste si někdy objednali online něco malého a pak byli rozzlobení, když vám daná věc přišla v nadměrně velké krabici vycpané papírem, bublinkovou fólií nebo vzduchem plněnými polštářky?

Dynamické doplňování na straně linky: strategická odpověď na současné výrobní výzvy

15. Červenec 2024 Pokud si výrobci chtějí udržet efektivitu a konkurenceschopnost a zároveň čelit výzvám, které přináší přizpůsobení a nedostatek pracovních sil, je čas přehodnotit systémy a postupy doplňování na straně linky. Mohly by být odpovědí na tyto výzvy systémy AMR a koboti? Trend přizpůsobování přinesl výrobcům řadu provozních výzev. Potřeba pojmout širší škálu komponentů a materiálů přináší variabilitu, kterou tradiční systémy jen těžko efektivně zvládají. To může vést ke zvýšení nákladů na zásoby, prodloužení dodacích lhůt a zpoždění výroby. Empirická data podtrhují dopad přizpůsobení na výrobní operace. Výrobci uvedli, že čelili prodlouženým dodacím lhůtám, vyšším výrobním nákladům a potřebě řídit více zásob. Tato čísla ilustrují hmatatelné výzvy, které přizpůsobení představuje a které vyžadují inovativní přístupy k efektivnímu řízení této složitosti.

Robotické trendy 2024: Jednoduchá a flexibilní aplikace nezbytná k dosažení plného potenciálu

03. Červenec 2024 Od nosiče nákladu přes kolegu až po týmového hráče: role robotů se za posledních sedm desetiletí výrazně změnila. Umělá inteligence vytváří další možnosti, ale rozhodujícím faktorem zůstává člověk. Roboti, nebo lidé – kdo bude v budoucnu určovat výrobu? Od roku 1954, kdy si George Devol patentoval programovatelný manipulátor, vyvolává tato otázka diskuse. Devolův robot Unimate způsobil revoluci v průmyslu tím, že bezpečně vykonával nebezpečné úkoly, a zdůraznil, že nejde o souboj robot vs. člověk, ale spíše rovnice „robot + člověk = efektivita“. V průběhu 70 let se požadavky průmyslu vyvíjely tak, aby upřednostňovaly flexibilitu, škálovatelnost, přizpůsobivost a udržitelnost. Roboti zvládají úkoly, které uvolňují lidem ruce, aby se mohli soustředit na činnosti s přidanou hodnotou.

Spojování bodů: Automatizace podávání pro konkurenční výhodu

18. Červen 2024 Vývoj v oblasti robotiky usnadňuje koncepci flexibilních systémů podávání a manipulace na straně výrobní linky, které mohou zvýšit bezpečnost, produktivitu a kvalitu a zároveň řešit nedostatek pracovních sil. Tovární automatizace obvykle začíná body. Máme tím na mysli velké, finančně náročné závody, které provádí komplexní a viditelné úkoly přidané hodnoty – ať už jde o průběžné balení, vstřikování, balení blistrů, plnění lahví, paletizaci nebo jiné hlavní výrobní procesy. Linie, které spojují tyto body dohromady – manipulace, nakládání a systémy podávání – bývají spíše řešené druhotně, a to až do té míry, že se tyto činnosti často provádějí ručně. Může se zdát, že je jednodušší a levnější mít obsluhu, která nakládá suroviny na výrobní linku nebo podává komponenty do strojů, než utrácet za automatizaci. Jedná se však o krátkozraký pohled, který opomíjí mnoho obchodních výhod, které může automatizované podávání a manipulace na straně výrobní linky přinést z hlediska efektivity, kvality produktů, škálovatelnosti a bezpečnosti a ochrany zdraví. Je to také názor, který je stále více zastaralý vzhledem k tlaku, který na výrobní odvětví vyvíjí současná krize práce.

Zavedení změny: Členění procesu flexibilní výroby

30. Leden 2024 Trh s rychloobrátkovým spotřebním zbožím prochází transformační změnou, která je vyvolána faktory, jako je posílení postavení spotřebitelů, požadavky na přizpůsobení, preference týkající se zdraví, veganství, etické obavy a udržitelnost. Očekáváme, že během příštího desetiletí dojde k většímu počtu změn než za posledních 50 let. Aby bylo možné novým trendům vyhovět, je potřeba přizpůsobit výrobu a dodavatelské řetězce. Továrny vyrábějící rychloobrátkové spotřební zboží budou mít v budoucnu pravděpodobně podobu menších, chytřejších zařízení s autonomním pohybem zboží a propojenými systémy.Aby bylo zajištěno včasné dodání příslušných materiálů a obalů, musí být stroje, ať už samostatné nebo propojené, flexibilnější než kdykoli předtím. Výroba musí být pružnější a je potřeba vyrábět čím dál více zboží připraveného pro maloobchodní prodej a nabízet širokou řadu produktů v malém množství a s nulovým stahováním z oběhu. Otázkou je, jak toho dosáhnout s minimálními náklady a rychlou návratností investic?

Co přinese rok 2024 v oblasti automatizace? Šest předpovědí od společnosti OMRON Europe

13. Prosinec 2023 Řada otřesů v posledních několika letech předznamenala novou éru zvýšených geopolitických a ekonomických rizik. Výrobci jsou nuceni k tomu, aby do obchodních modelů začlenili odolnost a flexibilitu a aby přehodnotili globální dodavatelské řetězce a vztahy. Zároveň stoupá tlak na začlenění principů ESG (ochrana životního prostředí, sociální aspekty a správa) do rozhodování o provozu. Pro vývoj řešení pro automatizaci a řízení, která mohou výrobnímu průmyslu pomoci se této nové realitě přizpůsobit, bude nezbytná umělá inteligence, datová věda, digitální dvojčata, technologie snímání a monitorování a kamerová technologie. V této souvislosti bych rád popsal šest hlavních trendů, které ovlivní průmyslovou automatizaci a budou ji formovat v roce 2024 a dalších letech.

4 nejlepší způsoby, jak řešit nedostatek pracovních sil pomocí automatizace

06. Září 2023 Automatizace je cesta k podpoře manuální pracovní síly, nikoli jejímu nahrazení.Nedostatek pracovních sil ve výrobě je celosvětově stále větší problém. Jako protiopatření se sice využívají finanční pobídky a cílená kvalifikace pracovní síly, ale jsou potřeba inovativnější řešení. Řada výrobců přistupuje k automatizaci opakujících se činností, ale do jaké míry tento způsob podporuje stávající pracovní sílu a do jaké míry ji už zcela připravuje o práci?V roce 2023 zveřejnila agentura Reuters alarmující trend: rekordních 53 % společností se potýká s problémy při přijímání zaměstnanců. Nedostatek zaměstnanců a prudce rostoucí náklady na energie v kombinaci se snahou o klimatickou neutralitu vytvářejí nové výzvy. Ve snaze o udržitelnou výrobu jsou majákem pokroku inovativní strategie, které řeší nedostatek pracovních sil a posilují stávající talenty.Pojďme si probrat čtyři nejdůležitější způsoby řešení nedostatku pracovních sil a podpory současné pracovní síly prostřednictvím automatizace:

5 nejlepších předpovědí společnosti OMRON Europe pro rok 2023 v oblasti automatizace

01. Únor 2023 Před námi je nový rok se všemi jeho příležitostmi, a proto bych rád upozornil na některé z hlavních trendů, které budou ovlivňovat a utvářet průmyslovou automatizaci v roce 2023 i v dalších letech. Výrobní průmysl bude i nadále čelit mnoha výzvám a jejich překonání bude vyžadovat budování odolnosti a flexibility v rámci obchodních modelů. Společnosti musí zároveň využívat nové technologie – senzoriku, robotiku, 5G a umělou inteligenci – k tomu, aby jim pomohly řešit problémy, kterým čelí v důsledku společenských výzev.

Klidný přístup v neklidné době: řešení ekonomické nejistoty přeměnou společenských problémů na technologické příležitosti

06. Prosinec 2022 Lidé se mě často ptají, jaká je naše strategie – jakožto divize průmyslové automatizace – pro udržení stabilního růstu v nestabilní a stále méně předvídatelné globální ekonomice. Jak si asi umíte představit, neodpovídám jednou větou, i když odpověď má svůj základ v jediném konceptu: SINIC. SINIC je akronymem pro „Seed-Innovation to Need-Impetus Cyclic Evolution“ a jedná se o teorii, kterou v roce 1970 vyvinul dr. Kazuma Tateisi, zakladatel společnosti OMRON. Podle této filozofie jsou věda, technologie a společnost v cyklickém vztahu, navzájem se ovlivňují a působí na sebe. Vědecké objevy pomáhají společnosti v rozvoji a společenské potřeby podněcují technologický pokrok. Společnost OMRON Europe se touto filozofií vždy řídila a v posledním desetiletí položila základy pro vytváření hodnotných řešení současných společenských a ekonomických problémů.

Čtyři tipy pro automatizaci pro malé a střední podniky

25. Listopad 2022 Vedoucí představitelé podniků po celém světě v současnosti čelí jedné výzvě za druhou: Kromě rostoucích nákladů způsobených energetickou krizí hrají roli problémy s dodavatelským řetězcem, nedostatek kvalifikovaných pracovníků, požadavky na udržitelnost a pokrok v otázkách digitalizace. Zejména malé a střední podniky musí rychle najít způsoby, jak tyto překážky vyřešit. Automatizace poskytuje nápravu, zahrnující robotiku, jako jsou koboty a AMR (autonomní mobilní roboty), dále senzory, kamerové systémy a technologie využívající umělé inteligence. I když si jsou společnosti dobře vědomy výhod těchto technologií, studie ukazují, že mnohé z nich vidí jejich skutečné využití stále skepticky.Zejména firmy bez zkušeností s aplikací mají strach, že použití robotů by mohlo znamenat vysoké náklady. Pokud tedy v současnosti přemýšlíte, zda nákup kolaborativního nebo mobilního robotu dává pro vaši firmu smysl, vyzkoušejte nový kalkulátor návratnosti investic OMRON. Poskytuje rychlý přehled o návratnosti investic a zobrazuje, kdy investice do robotiky pokryjí své náklady.

Digitalizace v automobilovém průmyslu: Sedm tipů pro chytrou výrobu

02. Listopad 2022 Chcete-li růst a zvládat krize, musíte být digitálně ve formě – a tak důležité odvětví, jakým je automobilový průmysl, není v tomto ohledu výjimkou. Abyste mohli oslovit zákazníky nebo řešit problémy s produktivitou, nevyhnete se digitálním nástrojům. Umělá inteligence a udržitelnost jsou klíčovými hnacími silami výrobců a hlavními tématy, na která se zaměřují, jak ukazuje studie společnosti Capgemini. Odborníci ze společnosti Gartner poukazují na význam celostních ekosystémů, technologických partnerství a přístupů založených na open-source spolupráci. Po čem bychom se ale měli dívat u digitalizace a intralogistiky ve výrobě budoucnosti? Na tuto otázku bychom rádi odpověděli ve dvou částech. Začneme s tipy na digitalizaci v chytré továrně. Společnost OMRON jako odborník na automatizaci již mnoho let doprovází výrobce a dodavatele na cestě k větší sofistikovanosti digitalizace.

Roadshow k flexibilní výrobě: Továrny budoucnosti na cestě Evropou

16. Červen 2022 Co kdybyste mohli zažít továrnu budoucnosti na vlastní kůži a vidět, co všechno obnáší flexibilní, efektivní a udržitelná výroba? Z této myšlenky se zrodila Roadshow k flexibilní výrobě společnosti OMRON, která letos vyráží na cestu po Evropě. Součástí roadshow jsou exkluzivní ukázky řešení spolupráce lidí a strojů, která za normálních okolností mimo továrnu neuvidíte, protože jsou zkrátka příliš velká.

Společně budujeme továrnu budoucnosti

16. Červen 2022 Jako jedna z největších obchodních jednotek ve společnosti OMRON chceme dále rozvíjet závod v Den Boschi tak, aby vyhovoval potřebám regionu EMEA.

Od optimalizace k autonomii – pět hlavních trendů automatizace výroby pro rok 2025 od společnosti OMRON

04. Leden 2025 S příchodem roku 2025 se blíží nová kapitola světa průmyslové automatizace. Podle teorie SINIC společnosti OMRON, která spojuje technologický pokrok se společenskými změnami, se nyní posouváme od optimalizace k autonomní společnosti. Teorie, kterou v roce 1970 vytvořil zakladatel společnosti OMRON Kazuma Tateishi, předpovídá budoucí společenský a technologický vývoj jako vodítko pro inovace. Ve fázi optimalizace se pozornost soustředila na zdokonalování procesů, zvyšování efektivity a využívání technologií ke zlepšení provozu. Autonomní společnost je ale zcela nová éra – doba, kdy systémy nefungují pouze efektivně; ale stávají se samoregulačními, samoučícími se a schopnými samostatného rozhodování.

První kroky k úspěšné digitalizaci

12. Listopad 2024 Vybudování digitální továrny není samo o sobě cílem ani důvodem. Digitální továrna je nástroj, který poskytuje výrobním podnikům flexibilitu reagovat na změny na trhu – ať už jde o inovační trendy, nebo zvyšování nákladů, a ať už působí v potravinářském a nápojovém průmyslu, osobní péči, farmaceutickém, nebo automobilovém sektoru.

Digitalizace s otevřenými standardy: Recept na kvalitní noční spánek

02. Září 2024 Můžeme se zavázat k mým predikcím? Dokážeme splnit termín? Mám dostatečný přehled, abych si mohl byl stoprocentně jistý? Jak si továrna vede z pohledu QCDE (kvalita, náklady, dodací lhůta a dopad na životní prostředí) v porovnání s našimi cíli a v porovnání s konkurencí? To jsou jen některé z obav, kvůli kterým nemůžou vedoucí továren spát – obav, které lze vyřešit pomocí digitalizace. V digitalizovaném výrobním prostředí se vedoucí továren nemusí obávat neznámých faktorů, rizik ani čehokoli, co by se mohlo přihodit. Digitalizace odbourává nejistotu a umožňuje dosažení optimalizace zaměřené na výkon. Přináší s sebou poznatky, které vedoucím továren pomohou zlepšit kvalitu, snížit náklady, zkrátit dodací lhůty a omezit dopad na životní prostředí. Vedoucí digitalizované továrny už se nebude muset uprostřed noci probouzet plný obav – ale pokud by se tak přeci jen stalo, krátký pohled na mobilní telefon ho ujistí, že vše funguje přesně tak, jak má. Přechod od probdělých nocí plných úzkosti k nocím naplněným poklidným spánkem ovšem není snadný. Dá se říct, že digitalizace může být celkem únavná. Vedoucí projektů si jen málokdy můžou dovolit luxus práce na nepopsané tabuli – většinou pracují s mozaikou starých technologií, které jsou tak nějak sešité dohromady; snaží se digitalizovat výrobní linky, jejichž součástí jsou stroje, které nikdy nezaznamenávaly data a byly postavené ještě před zrozením datových komunikačních protokolů. Kombinace tohoto všeho dohromady představuje značnou výzvu v oblasti integrace OT a IT.

Robotické trendy 2024: Jednoduchá a flexibilní aplikace nezbytná k dosažení plného potenciálu

03. Červenec 2024 Od nosiče nákladu přes kolegu až po týmového hráče: role robotů se za posledních sedm desetiletí výrazně změnila. Umělá inteligence vytváří další možnosti, ale rozhodujícím faktorem zůstává člověk. Roboti, nebo lidé – kdo bude v budoucnu určovat výrobu? Od roku 1954, kdy si George Devol patentoval programovatelný manipulátor, vyvolává tato otázka diskuse. Devolův robot Unimate způsobil revoluci v průmyslu tím, že bezpečně vykonával nebezpečné úkoly, a zdůraznil, že nejde o souboj robot vs. člověk, ale spíše rovnice „robot + člověk = efektivita“. V průběhu 70 let se požadavky průmyslu vyvíjely tak, aby upřednostňovaly flexibilitu, škálovatelnost, přizpůsobivost a udržitelnost. Roboti zvládají úkoly, které uvolňují lidem ruce, aby se mohli soustředit na činnosti s přidanou hodnotou.

Co přinese rok 2024 v oblasti automatizace? Šest předpovědí od společnosti OMRON Europe

13. Prosinec 2023 Řada otřesů v posledních několika letech předznamenala novou éru zvýšených geopolitických a ekonomických rizik. Výrobci jsou nuceni k tomu, aby do obchodních modelů začlenili odolnost a flexibilitu a aby přehodnotili globální dodavatelské řetězce a vztahy. Zároveň stoupá tlak na začlenění principů ESG (ochrana životního prostředí, sociální aspekty a správa) do rozhodování o provozu. Pro vývoj řešení pro automatizaci a řízení, která mohou výrobnímu průmyslu pomoci se této nové realitě přizpůsobit, bude nezbytná umělá inteligence, datová věda, digitální dvojčata, technologie snímání a monitorování a kamerová technologie. V této souvislosti bych rád popsal šest hlavních trendů, které ovlivní průmyslovou automatizaci a budou ji formovat v roce 2024 a dalších letech.

Snadný přechod na elektromobily: Tři největší výzvy, které je třeba překonat v automobilovém průmyslu

23. Listopad 2023 Přechod na elektromobily představuje pro výrobce automobilů náročnou cestu. Společnosti s dlouholetou tradicí, které vždy vyráběly vozidla se spalovacími motory, se nyní pokoušejí vstoupit do zcela nové oblasti platforem pro vozidla. Podívejme se na hlavní výzvy, kterým výroba elektromobilů čelí, a prozkoumejme nejnovější inovativní řešení na obzoru.

Setkání myslí: Konvergence IT/OT v průmyslové automatizaci

22. Září 2023 Výrobci, kteří se orientují na budoucnost, se blíží svým ideálům flexibilní, efektivní a udržitelné výroby tím, že důkladně zkoumají možnosti digitální transformace. S rostoucím zájmem o digitalizaci se však ukazuje, že mezi světy OT (provozních technologií) a IT (informačních technologií) zeje obrovská propast. A tuto propast je nezbytné překonat, pokud se mají dnešní vize továren budoucnosti stát zítřejší realitou. Než se však podíváme na to, proč je sbližování IT a OT nezbytné a jak toho lze dosáhnout, vraťme se o krok zpět k základům a pojďme si vyjasnit některá nedorozumění týkající se terminologie.

Podpora pracovníků: Přístup společnosti OMRON k rozvoji dovedností v evropské výrobě

06. Září 2023 Probádáme neochvějný závazek společnosti OMRON rozvíjet dovednosti, které posilují příští generaci, zatímco se průmysl vydává na cestu transformace – cestu, která uvolňuje plný potenciál čtvrté průmyslové revoluce (4IR) a zároveň odvážně směřuje k páté průmyslové revoluci (5IR).Na akademických půdách, v zasedacích místnostech vizionářských vedoucích podnikatelů a v kancelářích pokrokově smýšlejících politiků se vyvolává vášnivá debata. Točí se kolem toho, že hluboký posun od čtvrté průmyslové revoluce (4IR), nebo jak se také říká Průmyslu 4.0, k Průmyslu 5.0 změní svět, ve kterém žijeme.Z historického hlediska byla průmyslová revoluce prvním věkem strojů, elektřina druhým, elektronika pak třetím a internet jako platforma čtvrtým věkem strojů. Nyní vstupujeme do pátého věku strojů, který zdůrazňuje harmonickou spolupráci člověka a stroje a přínos průmyslu pro společnost. Nastal okamžik, kdy je třeba se nejen přizpůsobit, ale stát se vůdcem, průkopníkem a vytvářet budoucnost, v níž inovace nezná hranic. Klaus Schwab, zakladatel a výkonný předseda Světového ekonomického fóra, poznamenal, že: „Stojíme na pokraji technologické revoluce, která zásadně změní způsob, jakým žijeme, pracujeme a navzájem se k sobě chováme. Svým rozsahem, působností a složitostí se tato transformace nepodobá ničemu, co lidstvo dosud zažilo. Náš svět prochází transformační změnou. Globální výroba se vyvíjí a je poháněna automatizací tradičních průmyslových postupů prostřednictvím inteligentních technologií, komunikace M2M a integrace internetu věcí. Tato synergie pohání zvýšenou automatizaci, bezproblémovou komunikaci a inteligentní stroje, které samostatně analyzují a diagnostikují problémy.Vzestup umělé inteligence vyvolává debaty a naznačuje hlubší proměny v rámci našeho společenského vývoje. Jak hledáme cestu touto dynamickou krajinou, jsme připraveni přijmout inovace a přetvořit naši budoucnost.

Od červených světel po roboty: Společnost OMRON slaví 90 let inovací

06. Červen 2023 Při příležitosti letošního Dne zakladatele se společnost OMRON ohlédla za 90 lety, během kterých posouvala technologické hranice. S očekáváním vyhlíží další inovace v oblasti automatizace, které se ponesou v duchu udržitelnosti, digitalizace a spolupráce mezi strojem a člověkem.10. květen – velký den Každoročně představuje 10. květen pro společnost OMRON patrně ten nejdůležitější den v kalendáři. V tento den si 30 000 zaměstnanců společnosti OMRON po celém světě připomíná život a odkaz jejího zakladatele Kazumy Tateišiho. Znovu se hlásí k Tateišiho vizi pomáhat pomocí technologie vytvářet lepší svět a plní své společenské závazky – často účastí na dobrovolnických a charitativních projektech ve svých komunitách. Milníky inovace Inovacemi lemovaná cesta společnosti OMRON začala v roce 1933 vývojem vysoce přesného časovače pro rentgen. Tehdy naše společnost poprvé pomohla odpovědět na společenskou poptávku po řešeních problémů. V roce 1960 společnost OMRON představila první bezkontaktní bezdotykový spínač na světě a přinesla tak revoluci pokročilých možností hromadné výroby. Od té doby přicházela a nadále přichází s dalšími průlomovými technologiemi, včetně první automatické dopravní signalizace, systému bezobslužných vlakových stanic, nositelného monitoru krevního tlaku, ultrarychlého regulátoru s fuzzy logikou a zařízení pro automatickou diagnostiku nádorových buněk.

Umělá inteligence: Nejsem hloupá

08. Únor 2023 Před deseti lety jsem byl docela pyšný na to, jak chytré jsou stroje v naší továrně. Se svou dnešní definicí chytrosti si uvědomuji, že byly vlastně docela hloupé.Proč? Protože i když dělaly to, pro co byly navrženy, jakmile nastalo něco neočekávaného nebo neobyčejného, zarazily se. Nezbylo jim než se zeptat obsluhy: „Co je se mnou v nepořádku?“.Odstraňování problémů a opětovné zprovozňování strojů vyžadovalo chytré lidi. Vysoce kvalifikované pracovníky obsluhy. Zkušené softwarové a hardwarové inženýry. Problém je v tom, že v posledních deseti letech se tito lidé stávají stále nedostupnějšími. V tomto odvětví jednoduše není dostatek nových talentů, aby se vyrovnaly počty pracovníků, kteří se nyní blíží k důchodovému věku. Když tito lidé odejdou do penze, odnášejí s sebou své těžce nabyté pracovní znalosti, které jsou výsledkem mnohaletých zkušeností. S každým odcházejícím pracovníkem se podniky potýkají s perspektivou méně produktivní a méně kvalifikované pracovní síly.

Cesta k nulovým emisím: O taktice

01. Únor 2023 Klíčem k budoucnosti s nulovými emisemi ve výrobě je transformace hodnotového řetězce prostřednictvím automatizace.V červnu 2022 časopis New Scientist uvedl, že třetina největších světových společností si dala za cíl dosažení nulových emisí – výrazně více než ve stejné době v loňském roce.Ačkoli je pozitivní zprávou, že se tempo zrychluje, článek dále uvádí, že podrobnosti o tom, jak společnosti plánují dosáhnout nulových emisí, se liší.To ve skutečnosti není překvapivé. Vytvoření a implementace strategie nulových emisí je velkým závazkem pro všechny podniky, zejména pro ty s 80 % emisí skleníkových plynů, které spadající do rozsahu 3 – jedná se o emise, které se vyskytují v hodnotovém řetězci vstupu nebo výstupu. To je výzva především pro společnosti vyrábějící rychloobrátkové spotřební zboží (FMCG), jejichž dodavatelské řetězce a následná logistika jsou dlouhé a složité.Většina těchto podniků ví, co musí udělat: dekarbonizovat a cirkularizovat hodnotový řetězec. A mají strategii, která se bude obecně týkat optimalizace využívání zdrojů a energie, nahrazení produktů a procesů s vysokými emisemi a snížení odpadu.Hlavní výzva ale spočívá v převedení záměru do akce. Právě zde hraje klíčovou roli automatizace.Sběr a analýza dat jsou klíčem k úspěšnému přechodu na nulové emise. Jak by bez toho společnosti věděly, jaký je jejich výchozí bod, kde se musí zlepšit, zda se zlepšily a do jaké míry? Spolehlivé údaje jsou základem pro přeměnu závazku ve změnu a pro důvěryhodnou a správnou komunikaci se zúčastněnými stranami a plnění klimatických cílů.

Překonání energetické a palivové krize pomocí automatizace

07. Prosinec 2022 Pokud chtějí být průmyslové podniky schopné čelit rostoucím cenám a splnit své ekologické cíle, měly by prozkoumat možnosti, jak jim mohou automatizační technologie z jednoho zdroje pomoci se strategií udržitelnosti.Vysoké ceny energií a paliv zatěžují jak domácnosti, tak průmysl. Tato situace nejen negativně ovlivňuje finanční plány a odčerpává finanční prostředky, ale nadměrné ceny dokonce nutí některé společnosti zastavit výrobu. Podle organizace Make UK 42 % dotázaných výrobců uvedlo, že jejich účty za elektrickou energii se za posledních 12 měsíců zvýšily o 100 %, a 32 % dotázaných výrobců uvedlo, že ceny plynu se za poslední rok zvýšily o více než 100 %. Znepokojivých 12 % výrobců již v přímém důsledku zvýšených účtů za energie zrušilo pracovní místa.Válka na Ukrajině, pandemie nemoci Covid-19 a ceny plynu jsou jen některé z příčin krize, která má dopad na všechna odvětví a ovlivňuje vše od cen elektřiny až po dodavatelské řetězce. Co by nyní měly výrobní společnosti zvážit? K dosažení větší flexibility a energetické efektivity je nezbytné přijmout komplexní strategie automatizace. Ty zahrnují inovativní robotiku spojenou se senzorovými a kamerovými technologiemi, stejně jako umělou inteligenci – místně zpracovávané algoritmy umělé inteligence. Kromě toho mohou data z výrobních závodů dostupná v reálném čase pomoci při odhalování anomálií a zlepšování celkové efektivity vybavení (OEE).

Proč jsou automatizované kontrolní systémy zásadní pro výrobu elektrických vozidel

23. Březen 2023 Bezpečnost je v automobilovém průmyslu na prvním místě a výroba elektrických vozidel není výjimkou. Bezpečnost však může také znamenat složitost a složitost dnešních vozidel – a zejména těch elektrických – je taková, že výrobci již nemohou spoléhat na tradiční metody kontroly založené na vzorku nebo auditu.

Vadain automatizuje kontrolu záclonových tkanin pomocí strojového vidění

08. Duben 2022 Vadain, lídr na trhu se zakázkovými záclonami v Nizozemsku, potřeboval řešení pro co nejrychlejší detekci chyb v kilometrech záclonových tkanin. Společně s vývojáři softwaru ze společnosti Sycade, technologií strojového vidění OMRON a výrobcem strojů Eisenkolb vyvinuli automatizované řešení pro detekci a analýzu chyb v záclonových tkaninách, což z časově náročného procesu ruční kontroly dělá věc minulosti.

Factory automation: four tips for the future of food & beverage manufacturing

16. Červenec 2020 The coronavirus pandemic has posed major challenges to organisations of all types and sizes. In the food and commodity industry, companies have faced significantly reduced consumption and disrupted supply chains, while at-home consumption increased, and out-of-home consumption came near to a standstill. But how can manufacturers adapt their business strategies and production processes both now and in the longer term? The pandemic may provide an opportunity for rethinking outdated processes and procedures and enhancing them with concepts such as innovative robotics, sensor technology and holistic automation strategies.

Six challenges for brand protection

19. Listopad 2019 Brand protection is an important topic for any business. But as industrial companies invest in new technology, such as smart robotics, artificial intelligence and vision systems, are they aware of the key challenges that could affect their brand?

Legacy of machine vision

16. Říjen 2019 Did you know that for more than 40 years, Omron has developed vision sensing technologies for factory automation, surveillance and transport systems, and more recently for facial recognition and image processing for mobile phones, and even driver monitoring for autonomous driving?

Late-stage customization in pharmaceutical manufacturing

16. Říjen 2019 As a result of serialization legislation, pharmaceutical manufacturers must now ensure that labels printed at a late stage contain all of the data required for compliance. This includes customizing product labels for certain markets, customers or products by adding variable data to labels or packaging. This avoids the need to stock individual packaging materials for each variant.

How to secure FMCG supply chains with traceability?

02. Říjen 2019 The traceability of food and drink products throughout the production and distribution process can be a complex issue. For example, alcoholic drink producers need systems that enable them to comply with local regulations regarding food traceability, as well as tax legislation.

Barcodes: keeping track of product quality

02. Říjen 2019 For many years, barcode technology has proved to be an economical and flexible identification technology. It has continued to develop and as a result, 1D and 2D codes (such as Datamatrix) are now used almost universally. Their versatility have made them a popular choice for streamlining many key supply chain processes, including production, logistics and item traceability.

Is your production line ready for inspection?

12. Září 2019 Quality inspections are a critical requirement for all manufacturing and packaging lines. Being able to identify defective products before they are shipped to customers can bring significant savings in both time and money. It prevents costly product recalls, wasted production and potentially expensive legal costs.For perishable products – from food to pharmaceuticals – quality inspection of the packaging is also vital. An unreadable barcode or a wrong expiry date could lead to perfectly good products being discarded. And increasingly strict legislation is making clear marking a top priority for all types of products.

Nad rámec techniky kvůli technice: Co se stane, když se průmyslová automatizace setká s provozní dokonalostí

30. Listopad 2024 V posledních několika letech došlo k rychlému technologickému pokroku, přičemž jako klíčový trend vyčníval vzestup umělé inteligence. V průzkumu mezi výrobci ve Velké Británii, USA a Kanadě 70 % dotázaných uvedlo, že do svých operací implementovalo nějakou formu umělé inteligence. Tato ochota přijmout nové technologie je impozantní, zejména proto, že zpracovatelský průmysl může automatizací tolik získat.

První kroky k úspěšné digitalizaci

12. Listopad 2024 Vybudování digitální továrny není samo o sobě cílem ani důvodem. Digitální továrna je nástroj, který poskytuje výrobním podnikům flexibilitu reagovat na změny na trhu – ať už jde o inovační trendy, nebo zvyšování nákladů, a ať už působí v potravinářském a nápojovém průmyslu, osobní péči, farmaceutickém, nebo automobilovém sektoru.

Jak předejít omezení efektivity: Proč by společnosti neměly odkládat své plány ohledně robotiky?

24. Září 2024 Odkládání investic do inovativních technologií je spojeno s mnoha riziky. Firmy, které stále váhají, by si měly položit tři otázky.Evropská ekonomika čelí řadě výzev, které ovlivňují její růst, stabilitu a konkurenceschopnost. Evropa má například jednu z nejstarších populací na světě. Stárnoucí pracovní síla zvyšuje zátěž na systémy sociálního zabezpečení a snižuje nabídku pracovních sil, což potenciálně zpomaluje hospodářský růst. Kromě toho závazek EU k zelené dohodě a dosažení uhlíkové neutrality do roku 2050 vyžaduje značné investice a strukturální změny v různých odvětvích. K tomu se přidává nedostatek ochoty investovat kvůli finančním starostem. Nedávná studie McKinsey Global Institute (MGI) zjistila, že velké evropské firmy s více než 1 miliardou dolarů v příjmech zaostávají za svými americkými protějšky. Dohromady investují o 400 miliard dolarů ročně méně a rostou o jednu třetinu pomaleji.Tato investiční únava může vést k několika problémům, které mají krátkodobé i dlouhodobé dopady, včetně nevýhod, pokud jde o konkurenceschopnost, udržitelnost a pověst, nižší produktivitu a menší úspěch při získávání nových kvalifikovaných pracovníků. Inovativní robotika může takovému vývoji čelit, ale vyžaduje také dobře promyšlené financování. Firmy, které v současnosti omezují své investice, by si proto měly urychleně položit otázku, zda to pro ně nebude mít dlouhodobě negativnější důsledky než krátkodobé úspory. Tyto tři otázky by se měly zaměřit na tyto úvahy:

Digitalizace s otevřenými standardy: Recept na kvalitní noční spánek

02. Září 2024 Můžeme se zavázat k mým predikcím? Dokážeme splnit termín? Mám dostatečný přehled, abych si mohl byl stoprocentně jistý? Jak si továrna vede z pohledu QCDE (kvalita, náklady, dodací lhůta a dopad na životní prostředí) v porovnání s našimi cíli a v porovnání s konkurencí? To jsou jen některé z obav, kvůli kterým nemůžou vedoucí továren spát – obav, které lze vyřešit pomocí digitalizace. V digitalizovaném výrobním prostředí se vedoucí továren nemusí obávat neznámých faktorů, rizik ani čehokoli, co by se mohlo přihodit. Digitalizace odbourává nejistotu a umožňuje dosažení optimalizace zaměřené na výkon. Přináší s sebou poznatky, které vedoucím továren pomohou zlepšit kvalitu, snížit náklady, zkrátit dodací lhůty a omezit dopad na životní prostředí. Vedoucí digitalizované továrny už se nebude muset uprostřed noci probouzet plný obav – ale pokud by se tak přeci jen stalo, krátký pohled na mobilní telefon ho ujistí, že vše funguje přesně tak, jak má. Přechod od probdělých nocí plných úzkosti k nocím naplněným poklidným spánkem ovšem není snadný. Dá se říct, že digitalizace může být celkem únavná. Vedoucí projektů si jen málokdy můžou dovolit luxus práce na nepopsané tabuli – většinou pracují s mozaikou starých technologií, které jsou tak nějak sešité dohromady; snaží se digitalizovat výrobní linky, jejichž součástí jsou stroje, které nikdy nezaznamenávaly data a byly postavené ještě před zrozením datových komunikačních protokolů. Kombinace tohoto všeho dohromady představuje značnou výzvu v oblasti integrace OT a IT.

Co přinese rok 2024 v oblasti automatizace? Šest předpovědí od společnosti OMRON Europe

13. Prosinec 2023 Řada otřesů v posledních několika letech předznamenala novou éru zvýšených geopolitických a ekonomických rizik. Výrobci jsou nuceni k tomu, aby do obchodních modelů začlenili odolnost a flexibilitu a aby přehodnotili globální dodavatelské řetězce a vztahy. Zároveň stoupá tlak na začlenění principů ESG (ochrana životního prostředí, sociální aspekty a správa) do rozhodování o provozu. Pro vývoj řešení pro automatizaci a řízení, která mohou výrobnímu průmyslu pomoci se této nové realitě přizpůsobit, bude nezbytná umělá inteligence, datová věda, digitální dvojčata, technologie snímání a monitorování a kamerová technologie. V této souvislosti bych rád popsal šest hlavních trendů, které ovlivní průmyslovou automatizaci a budou ji formovat v roce 2024 a dalších letech.

Setkání myslí: Konvergence IT/OT v průmyslové automatizaci

22. Září 2023 Výrobci, kteří se orientují na budoucnost, se blíží svým ideálům flexibilní, efektivní a udržitelné výroby tím, že důkladně zkoumají možnosti digitální transformace. S rostoucím zájmem o digitalizaci se však ukazuje, že mezi světy OT (provozních technologií) a IT (informačních technologií) zeje obrovská propast. A tuto propast je nezbytné překonat, pokud se mají dnešní vize továren budoucnosti stát zítřejší realitou. Než se však podíváme na to, proč je sbližování IT a OT nezbytné a jak toho lze dosáhnout, vraťme se o krok zpět k základům a pojďme si vyjasnit některá nedorozumění týkající se terminologie.

Podpora pracovníků: Přístup společnosti OMRON k rozvoji dovedností v evropské výrobě

06. Září 2023 Probádáme neochvějný závazek společnosti OMRON rozvíjet dovednosti, které posilují příští generaci, zatímco se průmysl vydává na cestu transformace – cestu, která uvolňuje plný potenciál čtvrté průmyslové revoluce (4IR) a zároveň odvážně směřuje k páté průmyslové revoluci (5IR).Na akademických půdách, v zasedacích místnostech vizionářských vedoucích podnikatelů a v kancelářích pokrokově smýšlejících politiků se vyvolává vášnivá debata. Točí se kolem toho, že hluboký posun od čtvrté průmyslové revoluce (4IR), nebo jak se také říká Průmyslu 4.0, k Průmyslu 5.0 změní svět, ve kterém žijeme.Z historického hlediska byla průmyslová revoluce prvním věkem strojů, elektřina druhým, elektronika pak třetím a internet jako platforma čtvrtým věkem strojů. Nyní vstupujeme do pátého věku strojů, který zdůrazňuje harmonickou spolupráci člověka a stroje a přínos průmyslu pro společnost. Nastal okamžik, kdy je třeba se nejen přizpůsobit, ale stát se vůdcem, průkopníkem a vytvářet budoucnost, v níž inovace nezná hranic. Klaus Schwab, zakladatel a výkonný předseda Světového ekonomického fóra, poznamenal, že: „Stojíme na pokraji technologické revoluce, která zásadně změní způsob, jakým žijeme, pracujeme a navzájem se k sobě chováme. Svým rozsahem, působností a složitostí se tato transformace nepodobá ničemu, co lidstvo dosud zažilo. Náš svět prochází transformační změnou. Globální výroba se vyvíjí a je poháněna automatizací tradičních průmyslových postupů prostřednictvím inteligentních technologií, komunikace M2M a integrace internetu věcí. Tato synergie pohání zvýšenou automatizaci, bezproblémovou komunikaci a inteligentní stroje, které samostatně analyzují a diagnostikují problémy.Vzestup umělé inteligence vyvolává debaty a naznačuje hlubší proměny v rámci našeho společenského vývoje. Jak hledáme cestu touto dynamickou krajinou, jsme připraveni přijmout inovace a přetvořit naši budoucnost.

Od červených světel po roboty: Společnost OMRON slaví 90 let inovací

06. Červen 2023 Při příležitosti letošního Dne zakladatele se společnost OMRON ohlédla za 90 lety, během kterých posouvala technologické hranice. S očekáváním vyhlíží další inovace v oblasti automatizace, které se ponesou v duchu udržitelnosti, digitalizace a spolupráce mezi strojem a člověkem.10. květen – velký den Každoročně představuje 10. květen pro společnost OMRON patrně ten nejdůležitější den v kalendáři. V tento den si 30 000 zaměstnanců společnosti OMRON po celém světě připomíná život a odkaz jejího zakladatele Kazumy Tateišiho. Znovu se hlásí k Tateišiho vizi pomáhat pomocí technologie vytvářet lepší svět a plní své společenské závazky – často účastí na dobrovolnických a charitativních projektech ve svých komunitách. Milníky inovace Inovacemi lemovaná cesta společnosti OMRON začala v roce 1933 vývojem vysoce přesného časovače pro rentgen. Tehdy naše společnost poprvé pomohla odpovědět na společenskou poptávku po řešeních problémů. V roce 1960 společnost OMRON představila první bezkontaktní bezdotykový spínač na světě a přinesla tak revoluci pokročilých možností hromadné výroby. Od té doby přicházela a nadále přichází s dalšími průlomovými technologiemi, včetně první automatické dopravní signalizace, systému bezobslužných vlakových stanic, nositelného monitoru krevního tlaku, ultrarychlého regulátoru s fuzzy logikou a zařízení pro automatickou diagnostiku nádorových buněk.

Koupě, nebo leasing? Jak financovat nové koboty

26. Duben 2023 Podněty k zamyšlení pro malé a střední podniky při financování projektů automatizaceNedostatek dovedností, digitalizace, udržitelnost a plány úspor energie urychlují projekty automatizace v mnoha společnostech. Po identifikaci manuálních procesů, které lze automatizovat, následuje obvykle následující otázka: A kolik to všechno stojí?Může mít smysl zvažovat možnosti, jako je leasing nebo robot-jako-služba. Jedním z příkladů nástrojů, které poskytují zejména malým a středním podnikům (MSP) lepší přehled finančních aspektů automatizace, je kalkulátor návratnosti investic společnosti OMRON. Každý, kdo v současné době zvažuje nákup kobotů nebo AMR, může pomocí tohoto nástroje zjistit návratnost investice.

Jak urychlit integraci kobotu

08. Únor 2023 Dobré plánování a silní partneři pomáhají malým a středním podnikům překonávat překážky v automatizaci.Kolaborativní roboty, známé také pod označením koboty, se těší velké oblibě, protože umožňují automatizovat časově i zdrojově náročné úkoly. Celosvětový trh s kolaborativními roboty se v současné době odhaduje na přibližně 1,2 miliardy dolarů. Objem prodeje kobotů dosáhl v roce 2021 celkem 32 300 kusů. Zejména v době, kdy je pro společnosti stále obtížnější najít a udržet si vhodné zaměstnance, mají tyto technologie v mnoha případech cenu zlata. A když je řeč o zlatě, někdo by mohl položit otázku: Koboty jsou určitě extrémně drahé, že? Kdy se taková investice vyplatí?Společnost OMRON, odborník na automatizaci, by chtěla tyto obavy zmírnit, především u malých a středních firem – chytrá a integrovaná robotická řešení, stejně jako koboty a mobilní roboty, jsou proveditelná a cenově dostupná. Pro ty, kteří chtějí odhadnout návratnost investice, nabízí kalkulátor návratnosti investice společnosti OMRON rychlý a snadný přehled.Koboty a autonomní mobilní roboty (AMR) jsou vhodné jak pro malé a střední podniky, tak i pro velké společnosti. Provádějí úkoly, jako je přeprava, paletizace, nakládání a vykládání strojů, montáž, lakování nebo svařování. Je možné je rychle a flexibilně přenastavovat a mohou je programovat i neodborníci. Doplňování materiálu lze zefektivnit pomocí autonomních mobilních robotů a nakládání strojů a procesy pomocí kobotů. Pro úspěšnou realizaci takových projektů a urychlení integrace robotů je však zapotřebí know-how a partneři, kteří se v dané problematice vyznají. A především musí být do projektu od začátku zapojeni zaměstnanci, kterým musí být poskytnuty informace, aby se mohli společně podílet na změně.Zde je několik tipů, které by společnosti měly mít na paměti při integraci kobotů:

Umělá inteligence: Nejsem hloupá

08. Únor 2023 Před deseti lety jsem byl docela pyšný na to, jak chytré jsou stroje v naší továrně. Se svou dnešní definicí chytrosti si uvědomuji, že byly vlastně docela hloupé.Proč? Protože i když dělaly to, pro co byly navrženy, jakmile nastalo něco neočekávaného nebo neobyčejného, zarazily se. Nezbylo jim než se zeptat obsluhy: „Co je se mnou v nepořádku?“.Odstraňování problémů a opětovné zprovozňování strojů vyžadovalo chytré lidi. Vysoce kvalifikované pracovníky obsluhy. Zkušené softwarové a hardwarové inženýry. Problém je v tom, že v posledních deseti letech se tito lidé stávají stále nedostupnějšími. V tomto odvětví jednoduše není dostatek nových talentů, aby se vyrovnaly počty pracovníků, kteří se nyní blíží k důchodovému věku. Když tito lidé odejdou do penze, odnášejí s sebou své těžce nabyté pracovní znalosti, které jsou výsledkem mnohaletých zkušeností. S každým odcházejícím pracovníkem se podniky potýkají s perspektivou méně produktivní a méně kvalifikované pracovní síly.

Jakým směrem se ubírá intralogistika? Tipy pro vyšší efektivitu

15. Listopad 2022 Někdy se tolik zaměřujeme na celkový obraz, že zapomínáme na detaily, kterými jsou však důležité procesy charakterizující inteligentní výrobu. Příkladem je intralogistika, tedy toky materiálů a zboží, které probíhají v prostorách společnosti nebo ve výrobní hale. Nedávná studie zjistila, že více než 80 procent dotázaných společností považuje zvýšené využívání umělé inteligence a automatizace v intralogistice za nezbytnou součást řešení problémů, jako je nedostatek kvalifikovaných pracovníků nebo plány růstu.Automobilové společnosti, které chtějí splnit požadavky trhu a zákazníků, zvýšit efektivitu a stát se udržitelnějšími, musí přijít s novými nápady. Náklady na energii, plynová krize a rostoucí inflace činí tento úkol ještě obtížnějším. Inteligentní tovární koncepty, které kombinují inovativní automatizaci, digitalizaci a inteligentní vnitropodnikové přístupy, mohou poskytnout cennou podporu. Někteří v této souvislosti hovoří o průmyslu 4.0, jiní o „továrně budoucnosti“, další dávají přednost průmyslovému internetu věcí (IIoT). Ale bez ohledu na to, jaký termín upřednostňujete, je nejdůležitější být aktivní a spoléhat se na spolehlivé partnery. Intralogistika je dobrým výchozím bodem pro rychlé zahájení změny. Situace je taková, že je naléhavě zapotřebí přijmout opatření, mnoho společností je totiž v současné době značně omezeno nedostatkem kvalifikovaných pracovníků. Moderní technologie, jako jsou mobilní roboty, mohou poskytnout nápravu.

PPWR: proč jsou spolupráce napříč řetězci, sledovatelnost a inteligentní balení klíčové

24. Září 2024 Podle údajů Eurostatu vyprodukuje v roce 2021 každý obyvatel EU 188,7 kg obalů, což je téměř o 32 kg více než v roce 2011. Za toto období se množství plastového obalového odpadu zvýšilo o 27 %. Ačkoli se zvýšila i míra recyklace, stále se nerecykluje velké množství plastových obalů – podle nejnovějších statistik dosahuje 50% míry recyklace plastů pouze několik zemí v Evropě. Komise uznala, že stávající právní rámec nevede ke zlepšení v oblasti snižování množství obalového odpadu, a proto v roce 2022 navrhla revizi nařízení z roku 2018 o obalech a obalových odpadech (PPWR).Očekává se, že revidované nařízení PPWR vstoupí v platnost do konce tohoto roku a zásadně změní způsob navrhování, spotřeby a likvidace obalů. Aktualizované nařízení má široký záběr, ale jeho základním cílem je snížit množství vznikajících obalových odpadů a zvýšit recyklovatelnost obalů.

Čtyři největší výzvy, kterým výrobci elektromobilů čelí na cestě k dosažení udržitelné budoucnosti

17. Červen 2024 Elektromobily (EV) v posledních letech přešly ze specializovaného trhu na významnou průmyslovou sílu. Od roku 2023 tvoří elektromobily téměř pětinu prodaných vozidel, přičemž prodej vzrostl o 3,5 milionu kusů – což je podle Globálního výhledu EV 2024 IEA skok o 35 % oproti předchozímu roku. Očekává se, že tento nárůst bude pokračovat, přičemž odhady naznačují, že prodej na rozvíjejících se trzích v roce 2024 přesáhne 1 milion kusů, což oproti roku 2023 znamená 40% nárůst. Vlády po celém světě tlačí na snižování emisí CO2, což urychluje tento přechod na elektrická vozidla.Co to znamená pro výrobce automobilů? Za prvé to znamená, že musí přejít na navrhování a výrobu převážně elektrických vozových parků, což je krok, který již mnozí podnikli. Za druhé to znamená vybudování nových výrobních linek a zvládnutí nových výrobních procesů, což může být docela výzva.Právě zde přichází do hry důvěryhodný partner pro automatizaci. Partnerství s odborníkem v oblasti automatizace může pomoci zvládnout komplexní aspekty tohoto přechodu v celém odvětví. Díky širokému portfoliu technologií, globální podpoře a hlubokým odborným znalostem v oblasti automobilového průmyslu je společnost OMRON připravena vést výrobce na cestě k elektrifikaci.Tento příspěvek na blogu se bude zabývat hlavními výzvami v oblasti výroby elektromobilů a tím, jak může partnerství se společností OMRON poskytnout efektivní řešení:

Inteligentní automatizace jako hybatel změny

31. Květen 2024 Výrobní průmysl je zodpovědný za přibližně čtvrtinu globálních emisí skleníkových plynů¹, což jej řadí na druhé místo v podílu na emisích uhlíku, stejně jako dopravu. To znamená, že snížení uhlíkové stopy výrobního odvětví bude hrát zásadní roli při zmírňování našeho dopadu na změnu klimatu.Je načase, aby výrobní průmysl přestal být zdrojem problémů a začal naplňovat svůj potenciál tím, že se stane jedním ze zdrojů řešení, bude se zabývat změnou klimatu a využije automatizaci jako prostředek změny v tomto procesu.To odráží přesvědčení našeho zakladatele, že jako firma máme povinnost něco vrátit společnosti, ve které působíme. Před více než 90 lety se společnost OMRON zrodila z vize svého zakladatele Kazumy Tateišiho o využití technologií k vytvoření lepšího světa.Tateišiho étos „zlepšování života a přispívání k lepší společnosti“ nebyl vzhledem ke klimatickým výzvám, jimž jako společnost čelíme, nikdy relevantnější než v současnosti. Jak ale může výroba přinést pozitivní rozdíl?

I když to není rozbité, měli byste to opravit

04. Duben 2024 Udržitelnější výroba rychloobrátkového zboží díky inteligentnímu řízení spotřeby energie

Do toho, dámy! Objevte zajímavé kariérní příležitosti v oblasti automatizace

01. Březen 2024 Maryam Dolatabadi a Asunción Pastrana Costa jsou zkušenými odbornicemi na automatizaci ve společnosti OMRON. Vyzývají dívky a ženy: „Nebojte se, v tomto odvětví je vás naléhavě třeba!“

Průmyslová automatizace a robotika: Pořád ještě mužský svět?

07. Únor 2024 Jaké to je být ženou v dnešním prostředí automatizace? Tři ženy ze společnosti OMRON Europe hovoří o svých zkušenostech ve světě průmyslové automatizace, výzvách, kterým čelí, a o nástrojích a podpoře, které jim pomohly k úspěchu.Když Wendy Tonksová před více než 20 lety zahájila svou kariéru ve strojírenství ve Velké Británii, musela jako jedno z prvních pravidel stanovit to, že v práci není od toho, aby dělala čaj.

Co přinese rok 2024 v oblasti automatizace? Šest předpovědí od společnosti OMRON Europe

13. Prosinec 2023 Řada otřesů v posledních několika letech předznamenala novou éru zvýšených geopolitických a ekonomických rizik. Výrobci jsou nuceni k tomu, aby do obchodních modelů začlenili odolnost a flexibilitu a aby přehodnotili globální dodavatelské řetězce a vztahy. Zároveň stoupá tlak na začlenění principů ESG (ochrana životního prostředí, sociální aspekty a správa) do rozhodování o provozu. Pro vývoj řešení pro automatizaci a řízení, která mohou výrobnímu průmyslu pomoci se této nové realitě přizpůsobit, bude nezbytná umělá inteligence, datová věda, digitální dvojčata, technologie snímání a monitorování a kamerová technologie. V této souvislosti bych rád popsal šest hlavních trendů, které ovlivní průmyslovou automatizaci a budou ji formovat v roce 2024 a dalších letech.

Podpora pracovníků: Přístup společnosti OMRON k rozvoji dovedností v evropské výrobě

06. Září 2023 Probádáme neochvějný závazek společnosti OMRON rozvíjet dovednosti, které posilují příští generaci, zatímco se průmysl vydává na cestu transformace – cestu, která uvolňuje plný potenciál čtvrté průmyslové revoluce (4IR) a zároveň odvážně směřuje k páté průmyslové revoluci (5IR).Na akademických půdách, v zasedacích místnostech vizionářských vedoucích podnikatelů a v kancelářích pokrokově smýšlejících politiků se vyvolává vášnivá debata. Točí se kolem toho, že hluboký posun od čtvrté průmyslové revoluce (4IR), nebo jak se také říká Průmyslu 4.0, k Průmyslu 5.0 změní svět, ve kterém žijeme.Z historického hlediska byla průmyslová revoluce prvním věkem strojů, elektřina druhým, elektronika pak třetím a internet jako platforma čtvrtým věkem strojů. Nyní vstupujeme do pátého věku strojů, který zdůrazňuje harmonickou spolupráci člověka a stroje a přínos průmyslu pro společnost. Nastal okamžik, kdy je třeba se nejen přizpůsobit, ale stát se vůdcem, průkopníkem a vytvářet budoucnost, v níž inovace nezná hranic. Klaus Schwab, zakladatel a výkonný předseda Světového ekonomického fóra, poznamenal, že: „Stojíme na pokraji technologické revoluce, která zásadně změní způsob, jakým žijeme, pracujeme a navzájem se k sobě chováme. Svým rozsahem, působností a složitostí se tato transformace nepodobá ničemu, co lidstvo dosud zažilo. Náš svět prochází transformační změnou. Globální výroba se vyvíjí a je poháněna automatizací tradičních průmyslových postupů prostřednictvím inteligentních technologií, komunikace M2M a integrace internetu věcí. Tato synergie pohání zvýšenou automatizaci, bezproblémovou komunikaci a inteligentní stroje, které samostatně analyzují a diagnostikují problémy.Vzestup umělé inteligence vyvolává debaty a naznačuje hlubší proměny v rámci našeho společenského vývoje. Jak hledáme cestu touto dynamickou krajinou, jsme připraveni přijmout inovace a přetvořit naši budoucnost.

Od červených světel po roboty: Společnost OMRON slaví 90 let inovací

06. Červen 2023 Při příležitosti letošního Dne zakladatele se společnost OMRON ohlédla za 90 lety, během kterých posouvala technologické hranice. S očekáváním vyhlíží další inovace v oblasti automatizace, které se ponesou v duchu udržitelnosti, digitalizace a spolupráce mezi strojem a člověkem.10. květen – velký den Každoročně představuje 10. květen pro společnost OMRON patrně ten nejdůležitější den v kalendáři. V tento den si 30 000 zaměstnanců společnosti OMRON po celém světě připomíná život a odkaz jejího zakladatele Kazumy Tateišiho. Znovu se hlásí k Tateišiho vizi pomáhat pomocí technologie vytvářet lepší svět a plní své společenské závazky – často účastí na dobrovolnických a charitativních projektech ve svých komunitách. Milníky inovace Inovacemi lemovaná cesta společnosti OMRON začala v roce 1933 vývojem vysoce přesného časovače pro rentgen. Tehdy naše společnost poprvé pomohla odpovědět na společenskou poptávku po řešeních problémů. V roce 1960 společnost OMRON představila první bezkontaktní bezdotykový spínač na světě a přinesla tak revoluci pokročilých možností hromadné výroby. Od té doby přicházela a nadále přichází s dalšími průlomovými technologiemi, včetně první automatické dopravní signalizace, systému bezobslužných vlakových stanic, nositelného monitoru krevního tlaku, ultrarychlého regulátoru s fuzzy logikou a zařízení pro automatickou diagnostiku nádorových buněk.

Proč jsou automatizované kontrolní systémy zásadní pro výrobu elektrických vozidel

23. Březen 2023 Bezpečnost je v automobilovém průmyslu na prvním místě a výroba elektrických vozidel není výjimkou. Bezpečnost však může také znamenat složitost a složitost dnešních vozidel – a zejména těch elektrických – je taková, že výrobci již nemohou spoléhat na tradiční metody kontroly založené na vzorku nebo auditu.

5 nejlepších předpovědí společnosti OMRON Europe pro rok 2023 v oblasti automatizace

01. Únor 2023 Před námi je nový rok se všemi jeho příležitostmi, a proto bych rád upozornil na některé z hlavních trendů, které budou ovlivňovat a utvářet průmyslovou automatizaci v roce 2023 i v dalších letech. Výrobní průmysl bude i nadále čelit mnoha výzvám a jejich překonání bude vyžadovat budování odolnosti a flexibility v rámci obchodních modelů. Společnosti musí zároveň využívat nové technologie – senzoriku, robotiku, 5G a umělou inteligenci – k tomu, aby jim pomohly řešit problémy, kterým čelí v důsledku společenských výzev.